Monoclonal antibodies (mAbs) have become a major class of therapeutic agents on the market and represent a high value growth contributor to pharmaceutical portfolios.

These novel therapies present a unique set of upstream and downstream challenges for the pharmaceutical industry from formulation and characterization to regulatory, quality assurance, and delivery.

As in any drug development work, companies strive to reduce time to market, program cost and risk.

Specific challenges for mAb therapies:

Given these factors, an advisor with direct experience in mAb development is critical to driving your program’s success. The following five optimization strategies address challenges drug sponsors and pharmaceutical manufacturers encounter with mAb therapies:

Strategy 1: Institute an integrated development process

Workstream integration across the spectrum of development steps, from pre-clinical through commercialization, is necessary to address the complexities of mAb therapies, avoid risk, and shorten time to market. This is especially true if the drug sponsor is creating its first mAb product, does not possess in-house resources, or faces timeline constraints.

mAb development is a team effort that requires subject matter experts at each stage. But individual experts cannot work in isolation – alignment between them early and often is key. Unfortunately, lack of workstream integration produces delays and unforced errors that can derail the development process.

Looking at the development process in its entirety, it becomes clear where one area of expertise flows into the next. For example:

The most successful development programs put a priority on integration. Integration also helps catch small problems that can grow to become much larger issues if not identified early.

An experienced, objective mAb/biosimilar advisor with cross-functional knowledge can serve this oversight role, coordinating at multiple stages and ensuring an integrated approach is taken by the team, with the goal of maximizing cost efficiencies, reducing risks and realizing a rapid launch timeline.

Strategy 2: Proactivity reduces risk and saves time

The drug development process is a complex multi-faceted endeavor that requires that companies anticipate resource needs and workstream timelines. An important aspect of an integrated development approach is to understand how and when different sub tasks overlap and influence one another. Further, decision makers would be prudent to consider strategies that create program flexibility to enable proactive adaptation to challenges that occur along the drug development process.

Contingency plans should be built into every development roadmap in advance. Next actions should be detailed in anticipation of delays and setbacks that inevitably occur at various points in the CMC process. Without contingency plans, crises in the form of long development delays are inevitable but avoidable outcomes.

Contingencies apply not only at critical development stages, but in many other areas expected to present challenges. No drug sponsor wants to experience failures that force time-consuming backtracking or even the need to reimagine the existing roadmap.

Each mAb product, including biosimilars, are complex products that need tailored customized solutions to produce a successful development program. Being proactive at multiple levels requires knowledge of all mAbs development steps, regulatory and heath authority requirements, and, ideally, expertise in advanced manufacturing techniques. Pharmatech deploys a mechanism of action strategy to inform material characterization and create robust, successful regulatory arguments. Our CMC and Quality services enable regulatory feedback at the pre-IND stage to deliver a streamlined process development and control strategy.

Strategy 3: Analytical methods are core to mAb characterization

Drug developers are wise to address numerous detailed physical and biochemical properties when necessary to characterize mAb therapeutics. These include understanding molecular parameters such as purity and activity levels, determining which experiments should be used for characterization, validating the product and meeting regulatory requirements, and reproducing it in quantity.

The following example illustrates the interplay between these considerations during the development process.

Streamlined mAb Development

To support a biosimilar mAb being developed for a Biologics License Application (BLA), Pharmatech Associates was engaged to assess the process and recommend parameters that would yield reproducibly glycosylated molecules. The mAb had a complex glycan profile requiring very narrow specifications.

Pharmatech analyzed the analytical method and associated data, provided a comprehensive report, validated the scale-down process model, and characterized the production bioreactors outputs.

· Process controls: Our experts reviewed the bioprocess for manufacturing the mAb and determined and recommended the appropriate process controls to afford a quality product, consistently.

· Optimized Analytics: Our team reviewed and recommended optimization for the analytical protocols to accurately characterize the protein and glycosylation patterns.

· Product & Process Regulatory Validation: We assisted the client in providing validation for both product and process to meet accelerated timelines for FDA review and approval. Leveraging our experience not only streamlined the reviewed process but eliminated the potential rework that may have been required to supplement the BLA filing.

Swift analysis and insightful recommendations enabled our client to meet the demanding BLA timeline, resolve critical discrepancies, and ensure an approval after FDA review.

As this example shows, an objective mAb development expert can streamline and add value to the process in multiple ways, including:

Every mAb product is unique. Understanding a product’s function informs the roadmap of future CMC workstreams enabling early regulatory agency engagement. Pharmatech identifies and tailors strategies aligned with early agency feedback to anticipate issues in CMC strategy that pose program risk to avoid costly delays. Having experienced support and advanced analytics techniques that augment in-house capabilities can significantly reduce risk and speed time to market.

Strategy 4: Speed compliance and regulatory success with a Fast Track approach

Drug developers strive for an efficient regulatory approval process, one that anticipates and eliminates issues that cause delays with the regulatory process. The complex nature of mAbs and other biologics poses a unique challenge for the FDA.

Having a resource by your side with deep experience in navigating evolving mAb regulations and health authority requirements allows the development process to progress in sync with the expectations of the FDA and other regulatory bodies.

Engagement with the regulatory agencies early and often enables drug sponsors to better understand the emerging regulatory landscape. Drug developers can anticipate, identify, and address program deficiencies before issues become roadblocks that cause delays. From in process controls and regulatory agency interfacing to clinical data management, end of Phase meetings and BLA preparation Pharmatech meets client expectations to accelerate product approval.

The Regulatory Fast Track strategy applied by Pharmatech Associates effectively anticipates FDA queries. It incorporates them early in the development program to reduce risk and save time, effort, and money. In addition to anticipating regulatory queries, an advisor familiar with the varied pathways to approval − and how the FDA views different drugs, treatments, and clinical needs − can lead to process efficiencies, as shown in the following example.

Regulatory Fast Track Strategy saves three to six months mAb development time

An mAb client had an early-stage drug in development with positive clinical results in Phase I. We believed there was a reasonable chance that it would get fast track and breakthrough drug status.

In anticipation, we built three full-scale Phase I studies to simplify the CMC argument, making the BLA submission review much lower risk from an FDA perspective.

The drug went on to achieve breakthrough trial status, which allowed the client to

use the exact same three lots for their Phase II studies. This made FDA’s review very simple as comparability was not an issue, resulting in virtually zero regulatory risk.

We tightened up their analytical methods, finalized their specifications, filed in April, and received approval in October – saving the client a minimum of three months of review time and potentially up to six months in the overall review time. This allowed the client to launch several months faster.

Independent experienced advisors frequently work with regulators and have history with accelerated approvals. Agency interactions can manifest in multiple ways including, client/FDA interface, preparation through mock inspections, and presenting and defending client technologies and mAbs applications.

Strategy 5: Apply Pharmaceutical Continuous Manufacturing (PCM) technologies

Product quality and reproducibility are first principles in pharmaceutical manufacturing. The manufacturing process for high quality therapeutic agents should consider costs, time and supply chain at operating scale to realize overall drug life cycle value.

We recommend that advanced manufacturing technologies and PCM be evaluated for mAb production to achieve these milestones.

A joint initiative between Pharmatech Associates, our parent company US Pharmacopeia and the National Institute for Pharmaceutical Technology & Education assists pharmaceutical and biotech companies in learning and applying advanced technologies to pharmaceutical manufacturing. The Continuous Manufacturing Knowledge Center is an open-access resource for accessing the latest research, community, and related events.

The following example shows how anticipating and solving a manufacturing problem before a product launch made the difference between success and failure for one of our clients.

Integrating Drug and Device Quality Systems

One of small group of drug development consultancies to offer manufacturing expertise and QMS implementation, Pharmatech Associates assisted a multinational company in transferring its production process to a new CDMO and packager.

This was a combination product (drug in a pre-filled syringe with an auto-injector) and the CDMO and packager lacked experience with this combination.

During our analysis, we uncovered a critical specification error in the drug-device assembly process, which, if left unaddressed, would have caused significant delays due to components being accepted that ultimately would not run on the machinery.

We identified the error (found in the stack-up tolerances of each component and not obvious in the subcomponents) and revised the specifications. We then worked with each supplier to accommodate the tightened specifications and helped the client procure new materials and successfully launch the product with no disruptions.

Integrated services, collaboration, and expertise for mAb therapy development

For drug developers seeking assistance with mAb product development, Pharmatech Associates – together with our parent company USP – brings an extensive history of overcoming development, regulatory and manufacturing challenges.

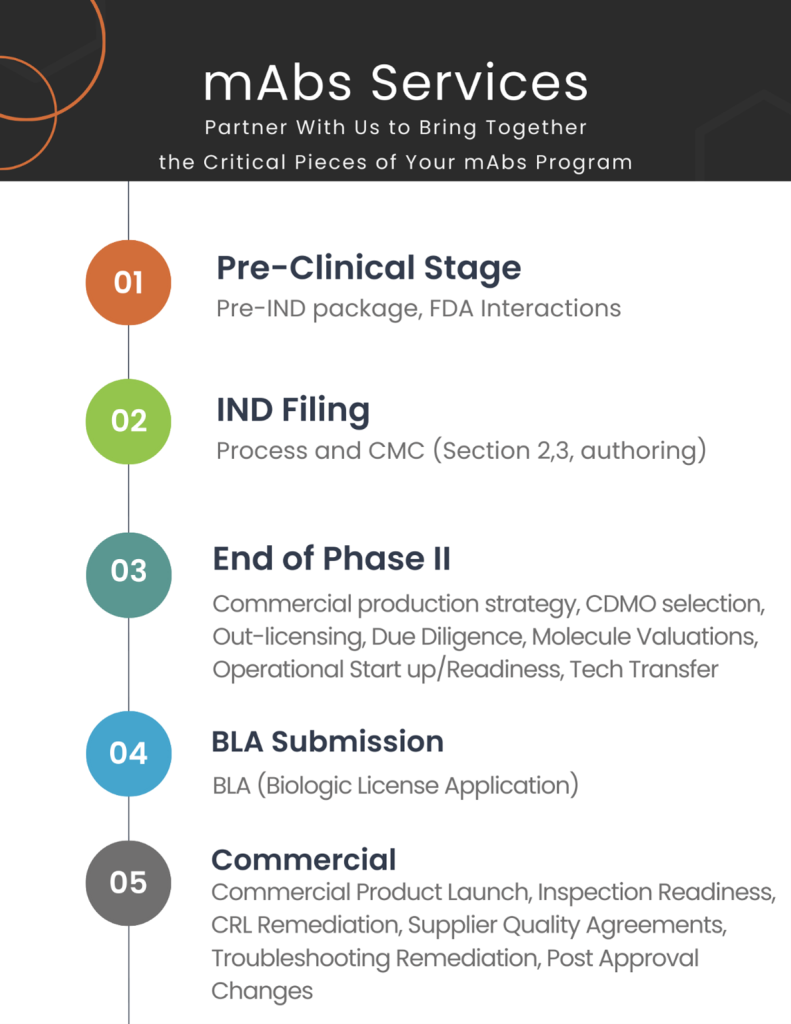

Our services (detailed below) enable drug sponsors to apply one or more of these proven strategies to bring mAb products to market faster.

Understanding program needs and expectations is key. We analyze mAb programs to identify critical program elements whether it entails method validation, process qualification, QMS strategy or PAI readiness and training. We can seamlessly integrate into your program as a senior advisor, offering guidance, addressing specific program elements, and collaborating on product, process, analytical, and regulatory strategy development to enhance your team’s capabilities.

Contact us to learn more about our capabilities and how we can help you with your next mAbs project.

Pharmatech Associates is the consulting arm of US Pharmacopeia (USP), a globally recognized leader in establishing drug quality standards for more than 200 years. From product development to navigating the regulatory landscape, we specialize in enhancing efficiency and bringing your products to market.

Our team is equipped with unparalleled knowledge and experience and is ready to partner with clients of any size, from startups to multinationals, in developing solutions across the pharmaceutical product and medical device life cycle.

Our unique approach can help your company navigate the complexities of launching a drug, biologic or medical device into multiple markets. The first step? Connecting. Simply fill out our form and a representative will follow-up shortly.

1.877.787.0177

510.732.0177

22320 Foothill Blvd. Suite 330, Hayward CA 94541